-

HAMWORTHY products

Pump systems

Hamworthy’s electric driven deepwell pumps offer a safe, reliable and energy saving alternative to hydraulic. Through extensive research, Hamworthy deepwell cargo pumps have been developed at Hamworthy Svanehøj for LPG/ethylene and combined LEG/chemical carriers.

The caisson installed seawater lift pump is based on Hamworthy Svanehøj’s well-proven deepwell pumps and has been developed to meet new customers’ requirements.

Deepwell cargo pumps

Water systems

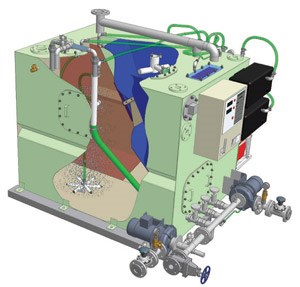

SewageTreatment Plant

Hamworthy is the world’s leading manufacturer of marine sewage treatment plants.For over three decades Super Trident sewage treatment plants have been widely regarded as standard specification on all vessels up to the largest cruise liners.

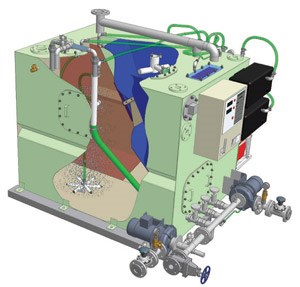

Membrane BioReactor System

Hamworthy Membrane BioReactor (MBR) produces the highest quality discharge without requiring any addition or generation of chemicals that are hazardous to the environment or ship operation.

Hamworthy Ballast Water Systems

Hamworthy’s range of AQUARIUS™ ballast water management systems offer owners and operators a choice of ballast water treatment solutions with greater flexibility.

Vacuum Toilets

The Hamworthy vacuum flush toilet has been designed to be mechanically simple, operationally reliable and stylish in appearance. It uses air to drive waste through the toilet and vacuum piping to the treatment tank or intermediate collection tank. This contemporarily styled toilet has a built-in vacuum breaker and flush memory. The control mechanism can be accessed without removing the bowl. By using only approximately 1 litre of water, a dramatic reduction in the amount of wastewater is realized.

WATER SYSTEMS ST-C SERIES

Gas systems

LPG & Ethylene Cargo Handling

Hamworthy is not only a leading supplier of gas carrier cargo handling technology, but also specializes in the design and manufacturing of key cargo handling equipment. For LPG and Ethylene carriers, Hamworthy offers single source services including engineering of complete cargo handling systems and tank design, as well as supplies cargo handling equipment.

LNG reliquefaction

Hamworthy’s reliquefaction system establishes a solution to liquefy the boil-off gas and return the LNG back to the cargo tanks.

LNG regasification

LNG regasification units are skid-mounted, very compact and can easily be arranged on deck. The LNG regasification unit by Hamworthy is designed for marine installations and for cryogenic working conditions.

VOC recovery

The field proven Hamworthy VOC recovery system is self supplied with energy and results in no VOC emissions.

Inert gas system

Flue gas

Hamworthy’s Moss Flue Gas Systems’ unique design is based on experience from thousands of installations.High efficiency, low maintenance costs, safe and easy operation combined with minimum space requirements are all important features of the Moss design.

Nitrogen Generators

Hamworthy’s nitrogen generators have been active in the marine market for almost 15 years. A new design has most recently been developed increasing nitrogen generators from niche, supplementary small-volume systems into large-scale main inert gas units.

The Moss Nitrogen Generator System is a compact and high efficient system based on air separation by use of hollow fibre membrane modules. Moss nitrogen generators use state-of-the-art membrane technology.This system is mainly for use onboard chemical carriers, gas carriers and FPSOs.

Moss Flue Gas System

Fire fighting system

Nitrogen generators